Ballmill السيليكا Eficiency القدرات

2017-10-17T04:10:52+00:00Ballmill السيليكا Eficiency القدرات

Factors Affect the Efficiency of Ball Mill

The feeding moisture of ball mill is required, generally less than 6% If it is above the standard, the material will adhere to ball mill during the grinding, thus resulting in lower productive efficiency of ball mill, and also blocking the air circulation channel and discharge opening of

ball mill silica eficiency capacity sremachineries

Factors Affecting Ball Mill Grinding Efficiency The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency a Mill Geometry and Speed – Bond 1954 observed grinding efficiency to be a function of ball mill diameter and established empirical relationships for recommended media size and mill speed

Ball Mill an overview ScienceDirect Topics

The degree of filling the mill with balls also influences the productivity of the mill and milling efficiency With excessive filling, the rising balls collide with falling ones Generally, filling the mill by balls must not exceed 30%–35% of its volume

ballmill silica eficiency capacity

ball mill silica eficiency capacity ball mill silica eficiency capacity We offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of Chat Now; grinding ball mill classifier silica sand Ball Mill (hebm) , high efficiency silica sand ball mill supplier , Grinding

Milling efficiency Magotteaux

Optimization in milling efficiency Magotteaux´s process engineers have worldwide experience and a database which covers about 80 per cent of the world´s mines We also have a complete range of tools and parts We have pilot plants and laboratory mills for SAG (semiautogenous grinding), secondary and ultrafine

ما هي مادة السيليكا " وأضرارها واستخداماتها المرسال

ماهي السيليكا السيليكا ، والتي تسمى أيضًا ثاني أكسيد السيليكون ، مركب من أكثر عنصرين وفرة في قشرة الأرض ، السيليكون والأكسجين ، SiO2 ، تبلغ كتلة القشرة الأرضية 59 في المائة من السيليكا ، وهي المكون الرئيسي لأكثر من 95 في

السيليكا جيل مجلة الباحثون المصريون العلمية

7 السيليكا جيل ثلاثة أنواع، النوع الأول الكريات فيه واضحة حيث أن قطر المسام حوالي 25 نانومتر تقريبًا، النوع الثاني فيه الكريات بيضاء شفافة وقطر المسام فيه يتراوح بين 45 – 7 نانومتر، أما النوع

ما هو عنصر السيليكون؟ موضوع

السيليكون (بالإنجليزية: silicon) هو عنصر كيميائي رمزه (si) يوجد في المجموعة 14 أو 4a، والدورة 3 من الجدول الدوري، أي من ضمن عائلة الكربون، ويشكل السيليكون نسبة 277% من تكوين القشرة الأرضية، ويعد ثاني أكثر العناصر وفرة في القشرة الأرضية بعد الأكسجين، [١] والعنصر السابع الأكثر وفرة في الكون، ويُصنف السيلسكون من ضمن أشباه الفلزات، ولا يوجد

استخدامات السيليكا جل (أكياس امتصاص الرطوبة )

السيليكا جل يتكون من مادة السيليكا و هي مادة شديدة الإمتصاص للرطوبة ، و ذات درجة حموضة عالية ، الأمر الذي يبين لنا الغرض من وضعها في الأحذية ،حقائب اليد، و كذا داخل علب الأجهزة الإلكترونية و ذلك للحفاظ على هذا النوع من السلع لمدة أطول لكونها معرضة للتلف من الرطوبة خاصة السلع الجلدية الالكترونية و الغذائية ايضا، إذ يتم اضافته بنسب مدروسة الى بعض

Ball Mill an overview ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig 212)Such a ball mill body is expedient because efficiency is appreciably increased Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix angle of balls is decreased

How to Improve Working Efficiency of Ball Mill

Control Feed Size The particle size of the material entering the ball mill is controlled between 2515 mm (the diameter of the ball mill is different for different feed sizes) Excessive rules will cause the ball mill to have too much fine material during the grinding process and cannot achieve the friction between the material and the material

ballmill efficiency

Five Steps To Increase Ball Mill Efficiency Essay ball mill is widely used in refractory plant, cement plant, glass plant and metallurgy plant etc,ball mill adopts roll bearing,its energy saving is reduced 30% than the overflow ordinary ball mill, low noise and high output efficiency make ball mill environmental protection,great wall company introduces the overall ball mill frame,it is

Continuous Ball Mill Continuous Type Ball Mill

Continuous ball mill has high production efficiency It can save the time of feeding and discharging, and improve the production efficiency to a certain extent Technical Data Specification(mm) Capacity(t/h) Feeding Size(mm)

Ball Mill Refining Kocotek

Our Ball Mill’s unique redesigned grinding vessel features a milling chamber with almost no deadspace Less product in the ball mill during grinding ensures optimum grinding efficiency, better temperature control, and leads to a

ballmill efficiency compare to other mills

Feb 05, 2019 Ball Mill Efficiency Compare To Other Mill The mill is equipped with a discharge diaphragm at the endhis diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground materiallosed circuit ball mill systemlinker, gypsum and other desired additives are fed to the

Wet Ballmill ETSTEYR

To get more efficiency that means to maximize the feed rate with minimum costs Integrated Twin Wet Ball Mill (ITWBL), that means we have a long tube that from outside look likes one ball mill with only two headwalls and two trunnions, one girth gear, one pinion, one pinion shaft, one GB, and one EM, one controlling system, one set of

ballmill efficiency

Ball Mill an overview ScienceDirect Topics The degree of filling the mill with balls also influences productivity of the mill and milling efficiency With excessive filling, the rising balls collide with falling ones Generally, filling the mill by balls must not exceed 30–35% of its volume Productivity of ball mills depends on drum diameter and the relation of drum diameter and length

Ball Mills Or Vertical Roller Mills: Which Is Better

Ball mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant This helps to reduce cost and complicated logistics issues The equipment cost is, however, higher for a

Formula Of Making Ceramic Ballmill Interior

formula 26 2339 3 s to calculate efficiency of ball mill is one of the biggest manufacturers in Aggregate Processing Machinery for the formula 26 2339 3 s to calculate Formula Of Making Ceramic Ballmill Interior Detail About ballmill mgp

Used Ball Mills Ball Mills for Sale Phoenix

700 HP Allis Chalmers Ball Mill Stock # 19490 Capacity 700 HP Used 700 HP Allis Chalmers 10ft x 14ft (3m x 43m) Ball Mill 2pc Helical Bull Gear, 13' diameter, 16" Wide Face, 310Teeth Helical Pinion Gear, 16" Wide Face, 19

Quality Mining Ball Mill Ceramic Ball Mill

High Return Iron Ore Mining Ball Mill Grinding Efficiency / Ball Milling Machine Intermittent Mining Ball Mill / Small Capacity Dry Grinding Ball Mill 1500×4500 Ball Grinding Machine Mining Ball Mill for Gypsum Limestone Iron Ore

ballMill Yantai Jinpeng Mining equipment, ore dressing

Large ball mill barrel professional processing lathe Power range is wide, high efficiency, low energy consumption, low noise, long service life To keep safe running, increase serviceability rate and prolong service life, must execute regular three kinds of maintenance as below:

Ballmill Efficiency Compare To Other Mills

Energy Efficiency Analysis Of Copper Ore Ball Mill Drive Mar 23, 2021 3 Analysis of Variant Ball Mill Drive Systems The basic element of a ball mill is the drum, in which the milling process takes place Figure1 The length of the drum in the analyzed mill without the lining is 36 m, and the internal diameter is 34 m The mass of

Factors Affect the Efficiency of Ball Mill

The feeding moisture of ball mill is required, generally less than 6% If it is above the standard, the material will adhere to ball mill during the grinding, thus resulting in lower productive efficiency of ball mill, and also blocking the air circulation channel and discharge opening of analysis ball mill etc

Ballmill Efficiency Compare To Other Mills

Energy Efficiency Analysis Of Copper Ore Ball Mill Drive Mar 23, 2021 3 Analysis of Variant Ball Mill Drive Systems The basic element of a ball mill is the drum, in which the milling process takes place Figure1 The length of the drum in the analyzed mill without the lining is 36 m, and the internal diameter is 34 m The mass of

Ball Mill Design/Power Calculation LinkedIn

Dec 12, 2016 Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a

ballmill efficiency compare to other mills

Feb 05, 2019 Ball Mill Efficiency Compare To Other Mill The mill is equipped with a discharge diaphragm at the endhis diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground materiallosed circuit ball mill systemlinker, gypsum and other desired additives are fed to the

ballMill Yantai Jinpeng Mining equipment, ore dressing

Large ball mill barrel professional processing lathe Power range is wide, high efficiency, low energy consumption, low noise, long service life To keep safe running, increase serviceability rate and prolong service life, must execute regular three kinds of maintenance as below:

(PDF) Energy Efficient Ball Mill Circuit ResearchGate

Jul 15, 2013 The perfect mixing ball mill and efficiency curve models were used to develop the base case model, which was used to simulate the

Ball Mill: Operating principles, components, Uses,

Jul 05, 2020 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size

Optimization of Cement Grinding Operation in Ball Mills

Jul 18, 2016 Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams – coarse and fines Changing the separator to a high efficiency type brings about better residue value (on 45 micron) for the same Blaine Alternatively, the cement can be

Bond EfficiencyGMGICEv1r04 Determining

µm Note that—in order for no correction factor for ball mill product fineness to apply—the ball mill circuit P80 should be no less than approximately 70 µm (Bond, 1962) This Bond Efficiency determination should not be applied to circuits with a P80 finer than approximately 70 µm without making qualifications 3

Resource Efficiency Ball

Approximately 87% of the total waste generated by Ball is metal manufacturing scrap All of that scrap is sent back to our suppliers and remelted so it can be reused in new metal applications Our waste management efforts focused on reducing the remaining waste streams which totaled 86, 110 thousand metric tons globally in 2021

Ball mills Metso Outotec

Reliable and quality mill for a lower cost Features With more than 100 years of experience in ball mill technology, Metso Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits

ballmill silica eficiency capacity

ballmill silica eficiency capacity asilonidofateefolletti Superfine Ball Mill China Wet Grinding Ball Mill Used for Silica Sand, Find details about China Silica grinding action and ore lifting capacity and decreases energy consumption 3:53 Technical data: Vibrating ball mill 4:3 Screen capacities Better efficiency

ballmill silica eficiency capacity

Addition of pebbles to a ballmill to improve grinding Jun 26, , Addition of pebbles to a ballmill to improve grinding efficiency , in power and ball consumption were achieved, with no loss in grinding capacity , tests on gold ore, in combination with balls, to mill silica sand (0615mm) live chat; Patterson Industries

Chocolate Ball Mill Gusu Food Processing Machinery Suzhou Co,Ltd

Gusu chocolate ball mill machine is an ideal equipment for highefficiency fine grinding of chocolate paste and similar lowfat slurries This highly efficient chocolate ball mill machine can be used alone (after mixing the slurry), but its characteristics are more pronounced when used in combination with a chocolate refiner as a separate or integrated treatment system

High Efficiency Energy Saving Ball Mill For Sale AGICO

Energysaving ball mill is a new kind of ball mill grinder developed by us for solving the shortcomings of ordinary ball mill, such as high energy consumption, low output, and low finenessIt is a highefficiency grinder in the ball mill series, which is widely favored by users In the production process, the energysaving ball mill reduces the energy consumption by 30%,

Ten Ways to Improve the Grinding Efficiency of

Here are ten ways to improve the grinding efficiency of ball mill 1 Change the original grindability The complexity of grindability is determined by ore hardness, toughness, dissociation and structural defects Small grindability,

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

Apr 22, 2019 Here are ten ways to improve the grinding efficiency of ball mill 1 Change the original grindability The complexity of grindability is determined by ore hardness, toughness, dissociation and

Ball Mill Plant high efficiency, low energy consumption

The ball mill plant is a grinding and classifying system consisting of a bucket elevator, a ball mill, a material bin, a cyclone collector, a deduster, an air blower, a packing machine and so on This is a new type of energy saving, high efficiency, large output, and high precision grinding production line, which combines superfine ball milling

ball mills efficient for chromite efficient

factors affecting ball mill grinding efficiency a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given

Choose right speed to improve ball mill grinding

In order for the ball mill to perform normal grinding operations, its working speed must be less than the critical speed Ball mills generally work in a “dropped” state There are many working speeds to achieve this working state, but there must

The way to improve the ball mill work efficiencyNews

The Ball Mill work efficiency influenced factors include water added, steel ball, raw material prescription, current, dispersant, slow, device and so on, the combination of factors that determine the ball mill work efficiency Ball mill to enhance the efficiency of work that is, from the six aspects to improve 1, ball mill’s water added The

ballmill efficiency

Nov 27, 2016 High Efficiency Working Principle Gm Ball Mill high efficiency ball mill work principle ball mill exporter What is a ball mill What are its uses and advantages The ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powder making production line including cement silicate new type building material refractory material fertilizer

ballmill silica eficiency capacity

Addition of pebbles to a ballmill to improve grinding Jun 26, , Addition of pebbles to a ballmill to improve grinding efficiency , in power and ball consumption were achieved, with no loss in grinding capacity , tests on gold ore, in combination with balls, to mill silica sand (0615mm) live chat; Patterson Industries

Resource Efficiency Ball

Approximately 87% of the total waste generated by Ball is metal manufacturing scrap All of that scrap is sent back to our suppliers and remelted so it can be reused in new metal applications Our waste management efforts focused on reducing the remaining waste streams which totaled 86, 110 thousand metric tons globally in 2021

Industrial Application Of Ball Mill AGICO

BALL MILL APPLICATION Ball mill is a type of grinding equipment for fine pulverizing crushed materials It further reduces the particle size of raw materials, generally applied in the material pretreatment stage in industrial production lines Compared with other grinding machines, it makes full use of resources, reduces energy consumption

ballmill efficiency

Dec 26 2017 nbsp 0183 32Several factors affect the efficiency of a ball mill for cement grinding In this article we shall be looking at some of these factors that have been proven to influence grinding efficiency Mill Geometry And Speed According to Bond 1954 the grinding efficiency of a mill depends on the ball mill diameter size of the

Energy efficient cement ball mill from

An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the ball mill is proven to do just that

Ballmill Silica Eficiency Capacity

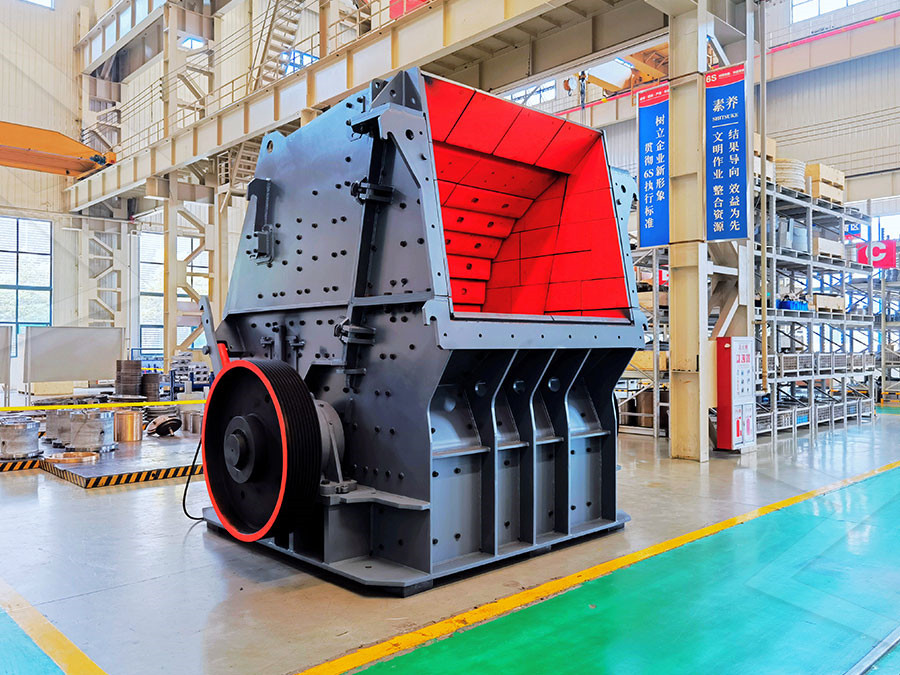

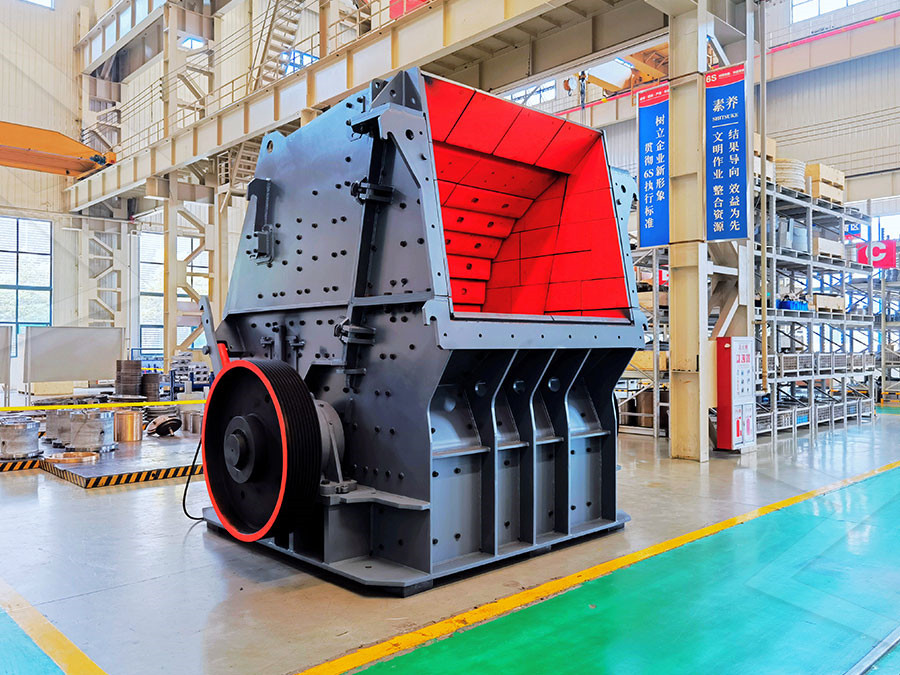

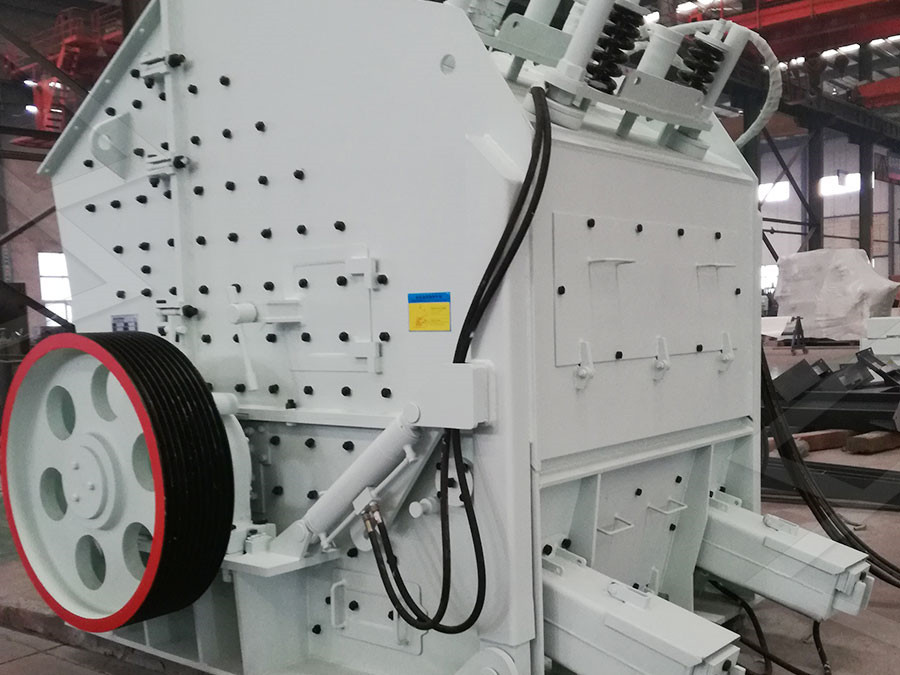

Silica sand ball mill is a new type of dry ball mill adapted to the production of silicon powder and improved and upgraded based on the traditional ball millThe whole working process of the ball mill is free of iron pollution and has a large capacity Silica Ballmill Indonesia Vaikuendokrinologijalt Ballmill Silica Eficiency Capacity